Every cement-based structure has its own inherent shortcoming—cement is brittle. As a result, it weakens when put through destructive forces like an earthquake or wildfire, is likely to give way and crumble. Researchers have now come up with a way to exploit the weakness of cement to make it actually get stronger if it cracks- this is similar to the way beetles and lobsters cope when their shells get ruptured.

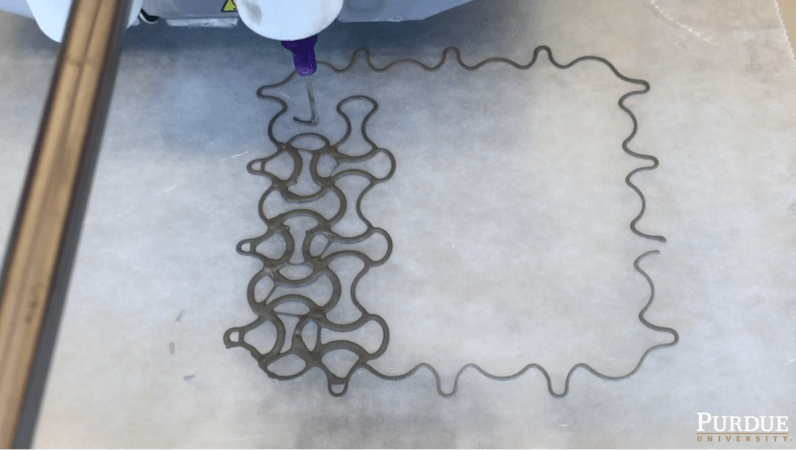

A team from the Purdue University has developed structures by 3D-printing cement paste—an important part of concrete—that gets actually tougher under pressure. The technique, notes a release put out by the University, could eventually lead to the development of structures that are resilient to natural disasters.

"Nature has to deal with weaknesses to survive, so we are using the 'built-in' weaknesses of cement-based materials to increase their toughness," said Jan Olek, of Purdue's Lyles School of Civil Engineering.

The idea is to print designs that are inspired by arthropod shells, notes the report, to control the spread of damage between printed layers of material. The researchers liken it to breaking a bunch of noodles, as opposed to a single noodle.

"The exoskeletons of arthropods have crack propagation and toughening mechanisms that we can reproduce in 3D-printed cement paste," said Pablo Zavattieri, Purdue professor of civil engineering.

The team reportedly took cues from the mantis shrimp, which hunts using a "dactyl club"- it is an appendage that grows tougher on every impact by twisting cracks, dissipating the energy with every blow, preventing it from falling apart.

3D-printed cement structures that use mortar and concrete would actually give engineers better control over design and performance of buildings, notes the report, but the technicality of printing large structures like homes or in some cases barracks, is complex and practical implementation is still not very easy.

This is why Purdue engineers turned toward bioinspired structures using cement paste, and 3D printing also removes the need for creating a mould for each type of design, so that it is possible to achieve the unique properties of cement-based materials that were not possible before, said Jeffrey Youngblood.

3D printing cement techniques include, notes the report, Honeycomb, Compliant, and Bouligand patters that the engineers called "architectures". Each of these architectures were found to react differently in a 3D-printed element once they dried and hardened. Bouligand architecture, for example, takes advantage of inherently weak interfaces to make materials more crack-resistant. The team found that Compliant architecture behaves like a spring, in spite of being made out of cement.

The study was first published in the journal Advanced Materials.