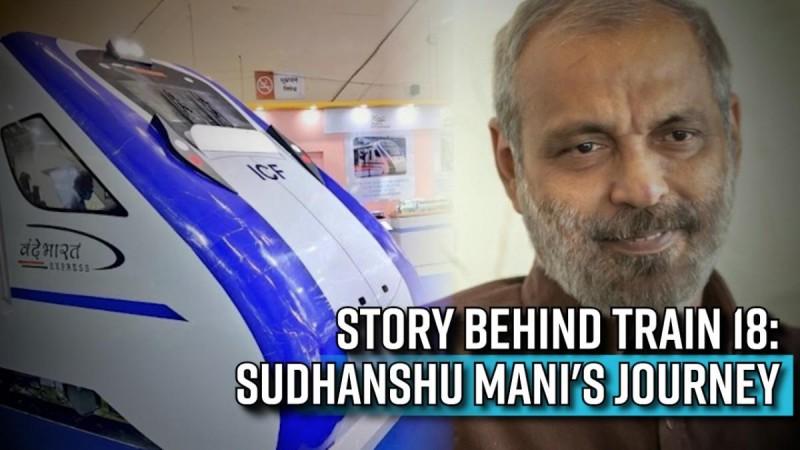

The news of manufacturing 400 Vande Bharat energy-efficient trains over the next three years made bold headlines after the announcement by Union Finance Minister Nirmala Sitharaman in the recent Budget speech. It indeed was a moment of great pride for the nation, and among those millions of brimming faces was Sudhanshu Mani, a humble railway officer who had much to contribute to this milestone.

Dr BR Ambedkar had once famously said: "Men are mortal. So are ideas. An idea needs propagation as much as a plant needs watering. Otherwise, both will wither and die." Sudhanshu Mani's singular dream was to deliver a modern train set for India and no amount of hurdles and obstacles could stop him.

The Vande Bharat Express or Train 18 is a semi-high speed train designed, developed and built by the ICF at an outlay of Rs 100 crore. It is one classic example of Make in India and far cheaper than similar trains that are rolled out by foreign companies. The train has only about 15 per cent import content which will further go down if production volumes increase.

But the story behind Train 18 (Vande Bharat Express) is one that evokes a true sense of patriotism. International Business Times reached out to Mani, retired General Manager, Integral Coach Factory (ICF) and now an independent consultant with decades of experience in the railways, to get a deeper understanding of how it all started, what were the challenges and how does it feel to be able to see the dream turn into a reality.

More importantly, Mani answers a few hard-hitting questions and shares crucial suggestions on how the government can function to achieve its set goals.

Excerpts from the interview:

IBT: As the creator of Train 18, now Vande Bharat Express, can you share with us a memory of the early days when you started this journey.

Mani: A modern train set was a long time coming. India needed a modern train set for decades but IR bureaucracy had repeatedly let the country down, immersed as it was in internecine battles and venal intentions to import. I asked for, and got the posting of General Manager of Integral Coach Factory, (ICF) in 2016, unlike others who opt for a bigger zonal railway posting, because I had this dream, and the vision to get a modern and fast train, with pleasing interiors and exteriors, designed and manufactured in India. I soon realized that the officers and staff of ICF had the right capability and the chutzpah to take up a project of a new train design and manufacture it de novo, from scratch.

The support industries in India had also reached near world-standard in certain key areas and was waiting a friendly nudge to excel themselves. All it needed was to channelize this energy to bring something noteworthy to fruition. This was going to be, in all likelihood, my last assignment before superannuation, after completing near life-long service of 35 years as a railway officer, including a rare stint in Germany in the Embassy of India as the Minister (Railways). So, I had the dream, the vision, the opportunity and the good fortune that a great team, raring to go, was bequeathed to me. I cherish the memories of those heady days which we spent in improving ICF in general and getting this train made in particular.

IBT: What were the early challenges you faced and what was the inspiration to keep going?

Mani: Well, challenges obviously were many but I will highlight some of them. The first was to get the Board to sanction the project. When I mooted the proposal, I met with derision, red tape and downright dismissal partly due to jealousy of some Board officials and partly due to roadblocks put up by the import lobby. I had to literally fall at the feet of the then Chairman but killing my vanity for the larger good was no problem. Then, there was the issue keeping the team motivated with the firm belief that the project would be a success, and that even in case of failure, there would be no attempt to find scapegoats.

Getting the right vendor-manufacturers to deliver the equipment and parts in time even as we were not able to deliver all drawings and technical specifications to them in time was a day to day challenge in the last six months of the project. And, of course, delivering the train in 18 months from concept to turn out involved disappointments on a daily basis and the trick was in not getting disheartened but to keep moving on with a fresh resolve.

IBT: 400 trains in 3 years is the target. What's your expert opinion on achieving it?

Mani: First of all, It is extremely gratifying to learn that the government has announced that 400 of these trains would be rolled out in the next three years. As the creator of the train, it is a moment of great pride for me and the team which built the first rakes 2018-19. It is also a vindication for me and the team as the project had been dragged into an unnecessary controversy since early 2019 and things improved after the new rail minster took over.

As for practicability, the immediate reaction in the media was that the announcement had overreached to an impossibility. But that is not important. Since the announcement in the budget speech of the country shows the intent of the government, the question should be how, and not whether, this can be achieved.

Let us check out a formula for realizing this dream-like announcement. Integral Coach Factory, Chennai is in the process of building, or ordering the equipment, for 102 trains. Assuming that this order can be enhanced by 30% as per IR's procurement regime, ICF can secure orders of equipment for 132 trains. I would propose that all these, barring a few, should be series-built in ICF alone, after the go ahead is obtained circa September 22 on completion of tests on the third and fourth rakes. Factories other than ICF have practically no experience of manufacture of 3-phase self-propelled trains and may cause deterioration in quality. At a feasible rate of 40 per year at ICF and the balance 12 at the two other factories, all these trains can be put on line by fiscal 2025-26.

That leaves a gap of 270 odd trains. One part should be built in IR factories on the lines of the Train 20 project, a project which is lying moribund since 2018. The other should be deployed by reviving the private trains project kept in limbo since July 21.

Train 20 was envisaged as an upgraded train set design, incorporating Aluminium body, which reduces the weight of the train and makes it more energy-efficient; these trains should be so designed that they are good for 160 km/h to 200 km/h speed range and therefore future-ready for the track being upgraded on select routes. The proposed contract should call for design as well manufacture in association with ICF engineers in hands-on mode. In addition, space should be provided within ICF to build the trains, barring the prototypes, in ICF itself employing IR staff supervised by contractors' experts. This will empower IR to develop future versions of the trains on their own. . It is feasible to see the prototypes of such trains sometime in fiscal 25-26 and after that a large number can be deployed in the next couple of years.

The project for private trains did not elicit interest from the prospective bidders as IR's babudom cussedly failed to address the concerns of the bidders in respect of an independent regulator, freedom to choose train timings, a comforting exit clause and one-sided revenue share regime. The contract can be refloated with a win-win attitude. This will help utilize the spare capacity of train manufacture in private sector of the country apart from affording world-class rail travel.

So, it is feasible to deploy 400 Vande Bharat trains or its clones. It may take five to six years instead of three but the government's intent can certainly fructify.

IBT: When you look back, what are you most proud of Vande Bharat Express?

Mani: That is easy to answer. The euphoria that Integral Coach factory, Chennai (ICF) witnessed on the days of the unveiling of Train 18, its breaching 180 km/h speed safely and its launch by the PM was so sublime that it is almost untellable. Team ICF had delivered the first modern train entirely of Indian origin from concept to delivery at much less than half the cost of import. It was after all just a train but the way the country loved and celebrated this Make in India project was beyond imagination.

I am very proud that I led a team that demonstrated the inherent capability of Indian engineers to develop, start to finish, a near world-class product in a record time of 18 months, which perhaps has no parallel.

Turning Train18 into reality in 18 months was a remarkable feat and it has been three years since the two trains are in successful service without any break in its service, a feat not paralleled by even any imported rolling stock so far. I must share full credit with the core team that ICF afforded to me.

IBT: Vande Bharat Express is indeed an overdue upgrade. Do you think this puts us at par with international standards, if not, how far are we from reaching that milestone?

Mani: I always call Train 18 near-world class. ICF did build a great train but not quite world-class. I wanted to, but there was a race against time as ICF was trying to do something in 18 months against the international norm of 36 to 42 months.

We are not far from international standard and now is the time to look at it very closely to turn out the new avatar of the train which must necessarily be an improvement over the first two. It has to rise above the bizarre creation of a new specification as it was nothing but an exercise driven by jealousy, venality and insipidity. It attempts to enhance the acceleration of a train that was at the optimum already or improve the ride of a train that has a ride-comfort superior to existing coaches. There are some technical issues to be addressed but, even those there are should be addressed strongly, like the improper ventilation of traction motors, unfriendly cable layout, disuse of Stepper in the Plug door etc. It is learnt that the Stepper in the Plug Door is being eliminated; that would be a defeatist way to solve a problem. In addition, based on the feedback from the field, we need to:

- Improve the seats as the European-type slide-forward seats were not appreciated by our travellers and back-rest reclining type seats should be employed, taking care that the integrity of the snack table be maintained,

- Inadequate holding space for catering needs to be augmented

- Improve the aesthetics in terms of uneven gaps in the panelling, better flooring, look of the LCD screens of the PIS should be reduced; this may need tightening the tolerances. The fire sampling points should be fitted in a pleasing manner.

- Modify the touch type reading lights

- Provide shatter-proof glasses of improved specification to withstand the stones thrown by miscreants

- There is no easy solution of the frequent damage to the nose of the train due to cattle run over cases as no nose, howsoever strong, can withstand the impact of a large animal hit at high speed; the Hobson's choice, therefore, is to replace cone sections to sustain this USP of the train unlike the ugly patch repair that we do today. A Cattle Guard in front would spoil the looks of the train front.

IBT: Of the challenges you might have faced, one that comes to mind is the case against ICF officials, of which you and 10 others were exonerated after two long years. What kind of setback did it bring, be it in terms of dedication or motivation?

Mani: The setback is for everyone to see. More than three years have passed but the third train is not in sight. The matter is closed but at least two core officers of the team have already suffered stalled progression in their careers. Is it not a very sad commentary on the ethos of the country, that the creators of a product which the PM himself praised on numerous occasions while addressing the nation, had to suffer such ignominy, precisely for daring to make this train whereas the perpetrators remain Scot-free. What more can I say?

By the way, I have covered the Train 18/Vande Bharat project and the interesting story that unfolded, over those 18 months and later in detail, with the same passion which saw the team go for it, in my book "My Train 18 Story", available on Amazon.

IBT: What is your ultimate vision for the Indian Railways (IR) and how can the govt materialise this vision?

My vision is very clear, Indian Railways will continue to remain the life-line of the nation and it must cater to the poorest, the commonest man, first, and all of them must be afforded air-conditioned travel in a matter of 15 to 20 years.

Believe me, it is possible. At the same time, IR should not only improve its trains and speed them up to offer competition to road and air for the richer segment of travellers but also target good revenue for itself from these services. At the same time, IR must win back modal share of cargo traffic from road and this can be done by imaginative schemes and designs.