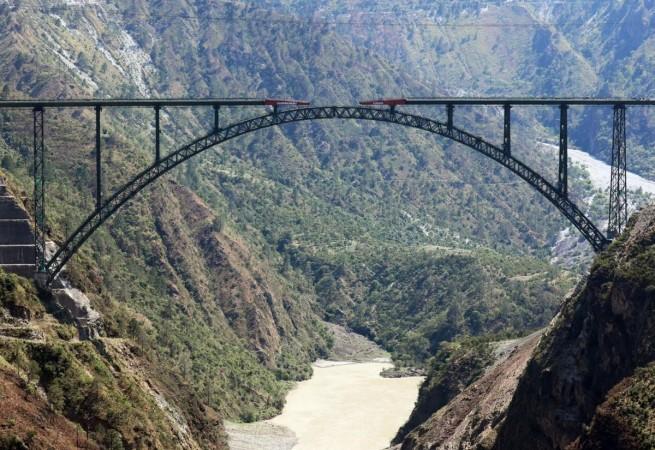

In a major milestone on the world's highest single-arch railway bridge over Chenab River, the overarch deck launch is scheduled for completion within a week, with a 'golden joint' linking the two sides, in the Union Territory of Jammu & Kashmir, excited officials said here on Friday.

The 1.315 kms long bridge -- which is being built at a dizzying height of 359 metres -- can fit the entire Eiffel Tower (330 metres tall), plus roughly a 10-storied tall building below it.

When completed, it will connect the Salal-A and Dugga railway stations on either side of the bridge with the mighty River Chenab gushing below in the picture-postcard Reasi district.

"Both ends will finally meet to complete the bridge overarch deck and the segments will be joined with the help of High Strength Friction Grip (HSFG) bolts to mark the critical 'golden joint' on the iconic structure. This will complete the Chenab River bridge, 359 metre above the riverbed, an extraordinary achievement and heralding a new chapter in the history of J&K," Afcons Infrastructure Ltd. Deputy Managing Director Giridhar Rajagopalan told IANS in Mumbai.

The bridge comprises 93 deck segments, each weighing around 85 tonnes, launched simultaneously from both ends of the valley over the massive steel arch and work on joining five segments in in full progress on the single line linking Katra (Jammu) with Qazigund (Kashmir), some 75 kms away, he said.

The project is part of the ambitious 272-kms long railway line from Udhampur to Baramulla joining Jammu with the Kashmir valley as an all-weather highspeed alternative, named the 'Udhampur-Srinagar-Baramulla Rail Link Project'.

The bridge has so far gobbled up around 30,350 tonnes steel, comprising 10,620 tonnes to build the gigantic arch and 14,500 tonnes for the bridge deck, and stands majestically near the Kauri village on the upstream of Salal Dam.

Explaining the high-tech that has gone into the construction, Rajagopalan said that for the first time in Indian Railways, incremental launching was done on transition curve and a longitudinal gradient, both at the same location, for the deck launching of the viaduct portion on the bridge.

Normally, bridges are built incrementally on a straight or curved platform with a uniform radius, and executing launching activities in inclement weather with stormy winds was extremely challenging, and Northern Railways and Konkan Railway Corporation Ltd played a big role in finalising the bridge design, he added.

Given the height, the extreme weather conditions and strong gales that often lash the valley, the sophisticated automatic signalling system installed on both sides will stop the trains from crossing the bridge if wind speeds there touch 90-kmph.

Stressing on quality and safety, a NABL laboratory was set up at the Afcons site to monitor quality at all stages, weld sample tests, etc, saving huge time, and NR permitted the use of Phased Array Ultrasonic Testing Machine to inspect welds for the first time in the country.

The access roads to the project site helped generate local employment while providing connectivity to several remote villages in the region, the fabrication work was carried out in workshops at both ends with the heavy and bulky segments transported to the launch pad using a specialised modular trailer, said Rajagopalan.

The Afcons team of engineers also designed a launch platform with a segment lifting capacity of 120 tonnes for a height of around 39 metre, developed and implemented several other innovations to overcome the various challenges of the treacherous mountainous terrain.

The 272-km long railway line will have 38 tunnels (total length 119 -kms) with the country's longest tunnel T-49 (12.75 kms), 927 big and small bridges (total length 13 kms), and mark a new era in the development and progress of Jammu & Kashmir, said officials.