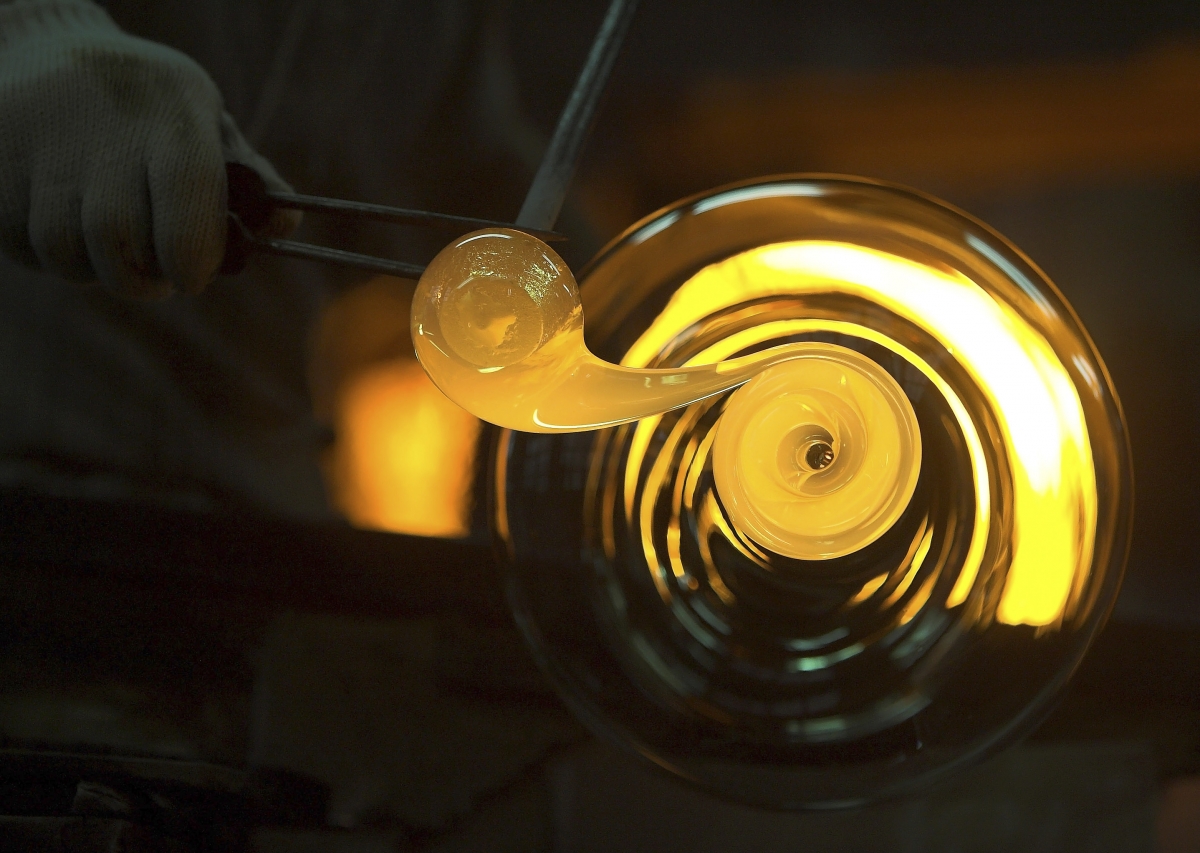

Glassblowing isn't for the faint-hearted; it's almost as risky as playing with fire. The handling of molten glass is crucial to the shape and size of the structure and that's where the technique (glassblowing) steps in.

At hot shops, batches of glass (mixed) are placed into a furnace and then melted in temperatures at 1,100 degree Celsius. Glassblowing is challenging and thus needs a team of few to get the job done. Once the glass has changed its state into liquid, a gob of it is taken out of the furnace with the help of an iron pipe measuring over four metres. The gaffer then blows into it to make bubbles of out glass. After the glass has attained shape as designed by the glass workers, it is then further rolled and sculpted on a marver, which is essentially a large surface.